Neat electrochemical cell design by @dlin and folks as part of a workflow involving “seven robots with automated modules for gas diffusion electrode fabrication and characterization and an automated test cell (ATC) that performs zero-gap CO2 electrolysis”:

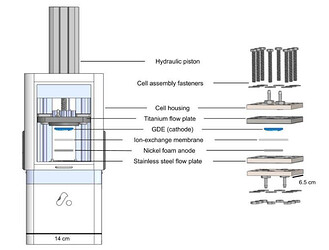

Comparison of the models of the automated test cell (ATC) described herein and a manually assembled electrolyzer. The ATC is structured similarly to a manually assembled electrolyzer using the same stack of flow plates, cathode, anode, and ion-exchange membrane. However, the ATC has no assembly fasteners but instead uses a hydraulic piston to automatically close the cell. The data acquisition and processing, including experimental conditions and the calculation of Faradaic efficiency (FE), is completely automated for the ATC system.

Design of ATC cathode and anode plates. The anode flow plate is made from stainless steel and has a 1 mm deep × 1 mm wide channel that was machined in a serpentine pattern with an active area of 20 mm × 20 mm. The cathode flow channel plate has the same features as the anode but is made from titanium. Around the channels of each plate is an O-ring groove with an embedded Viton O-ring to aid in sealing the cell when pressure is applied. Each flow channel plate is embedded in a 3D-printed, plastic housing which incorporates ports for inlet and outlet fittings, as well as mounting features to the aluminum frame of the ATC.

Photograph of the ATC platform showing individual components.

@dlin feel free to weigh in with other thoughts or lessons learned from the automation side of this.